Excessus Enterprises

Digital Design. Local Fabrication. Real-World Results.

Bridging the gap between creativity and precision manufacturing — from concept to production, we design, prototype, and fabricate unique parts and products with modern digital tools.

About Our Mission

At Excessus Enterprises, we help creators, makers, and small businesses turn ideas into tangible products.

We're a design-to-manufacture startup integrating 3D printing, laser cutting, and CNC milling into a streamlined creative service. Our mission is to make professional-grade design and fabrication accessible to individuals, startups, and small manufacturers who need custom, one-off, or low-volume production.

Work Portfolio

Real-world projects showcasing design, iteration, and functional prototyping

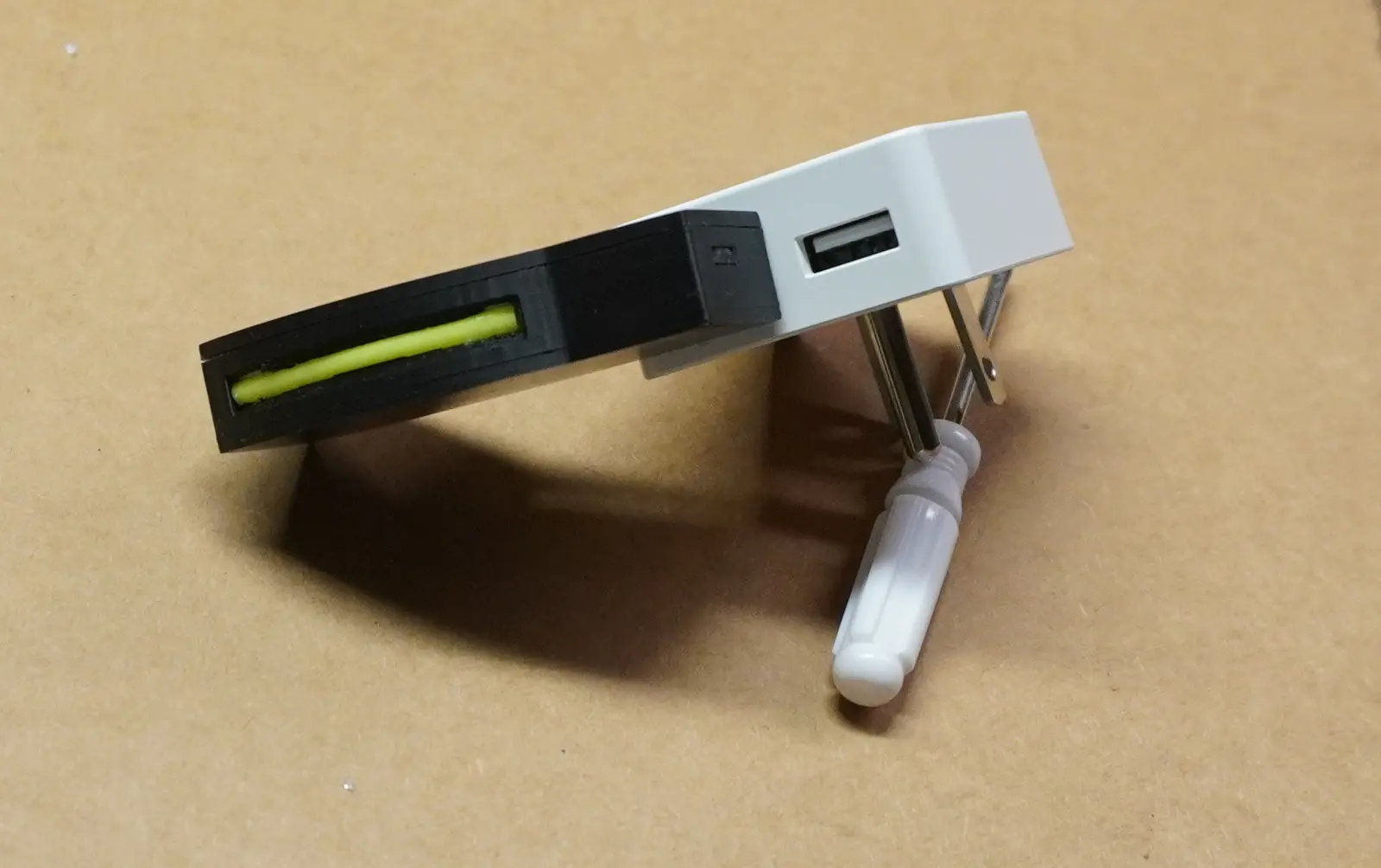

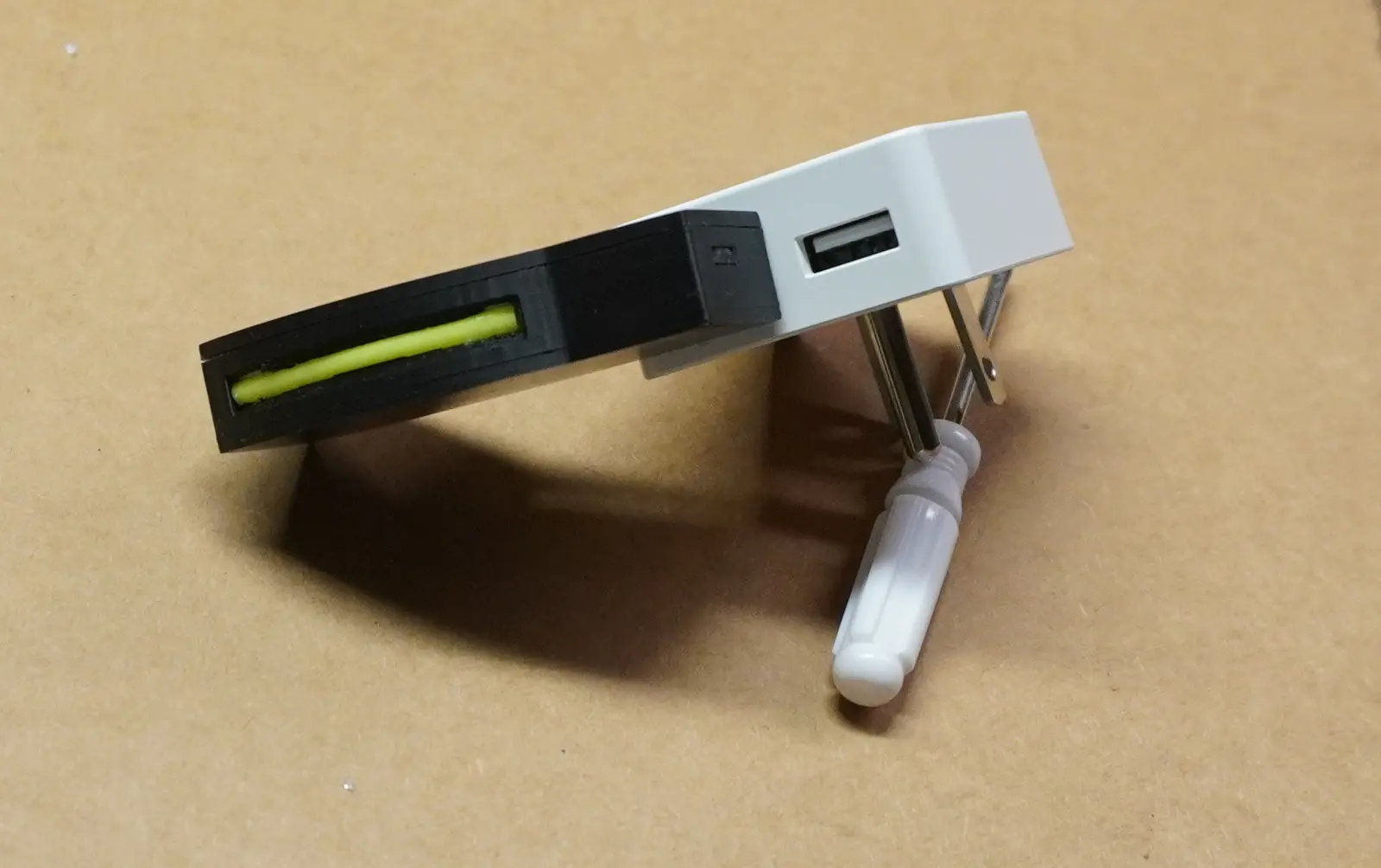

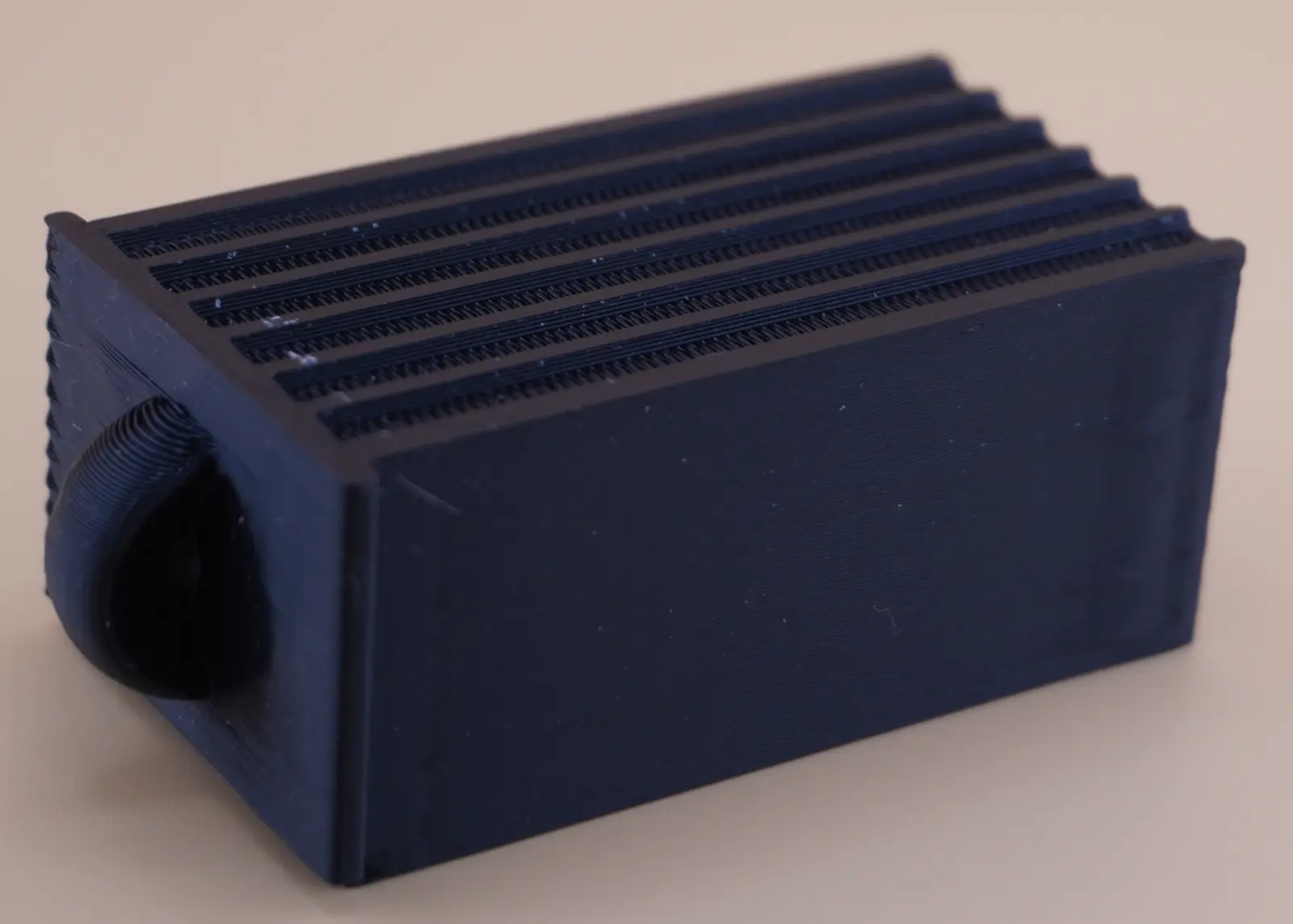

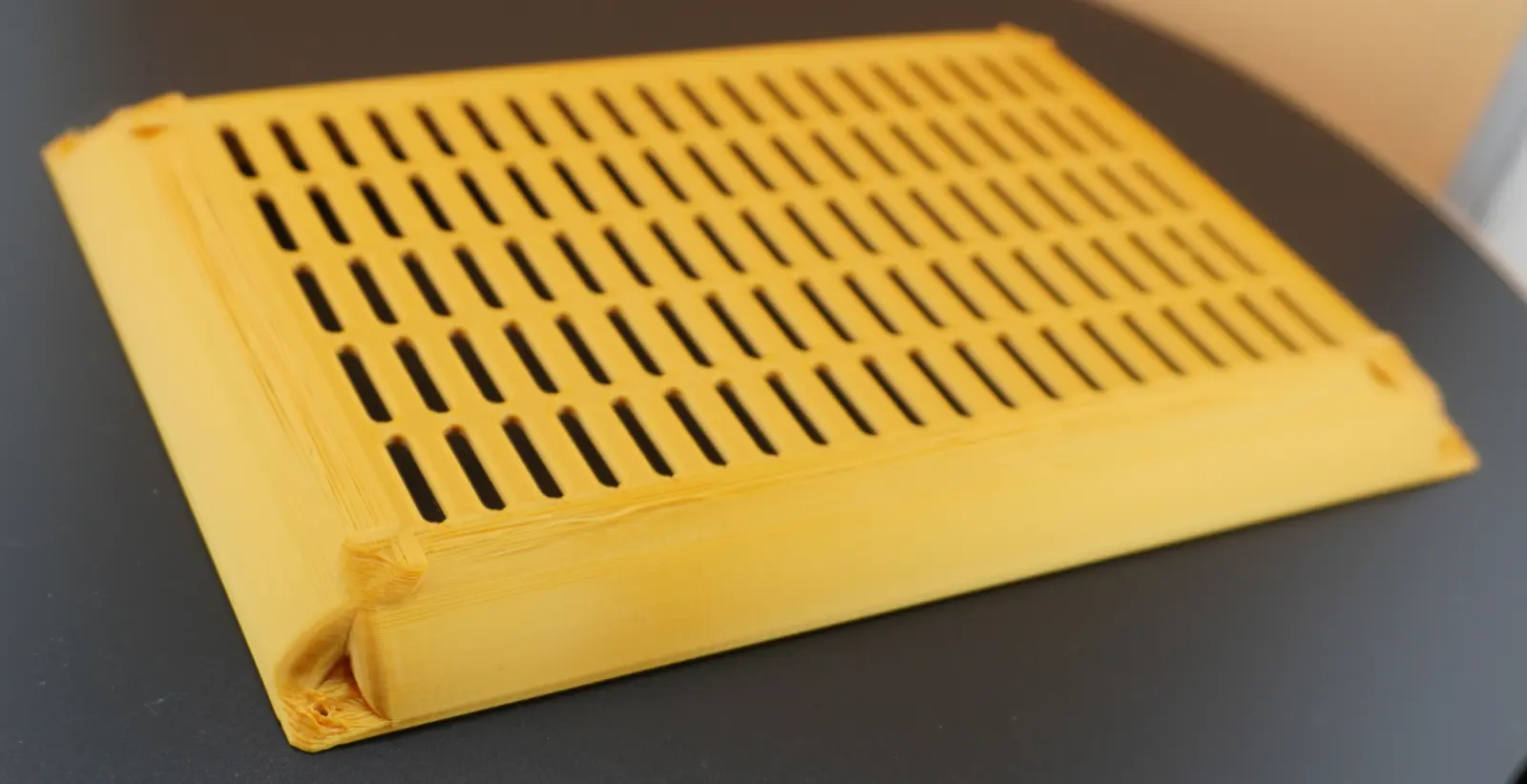

Hallway Motion Nightlight (v1)

Motion-Ready LED nightlight for low-light navigation

- • PIR sensor and ESP32-like microcontroller ready

- • Designed to extend non-blocking for extra components

- • USB based power fits economical outlet power adapters

- • LED strip has integrated diffuser and resistors

Watering Can with Combo Spout

Stable weighted base with embossed branding options

- • Multiple branding variants tested for visual appeal

- • Weighted design for improved stability

- • Threaded caps for interchangeability

- • Pour and shower in one cap

Fish Food Shaker (Threaded + Dispensing)

Precision-dispensing container with threaded lid

- • Controlled portion dispensing

- • Customized for specific food blends

- • Prevents accidental food "dumping"

- • Food-safe material considerations

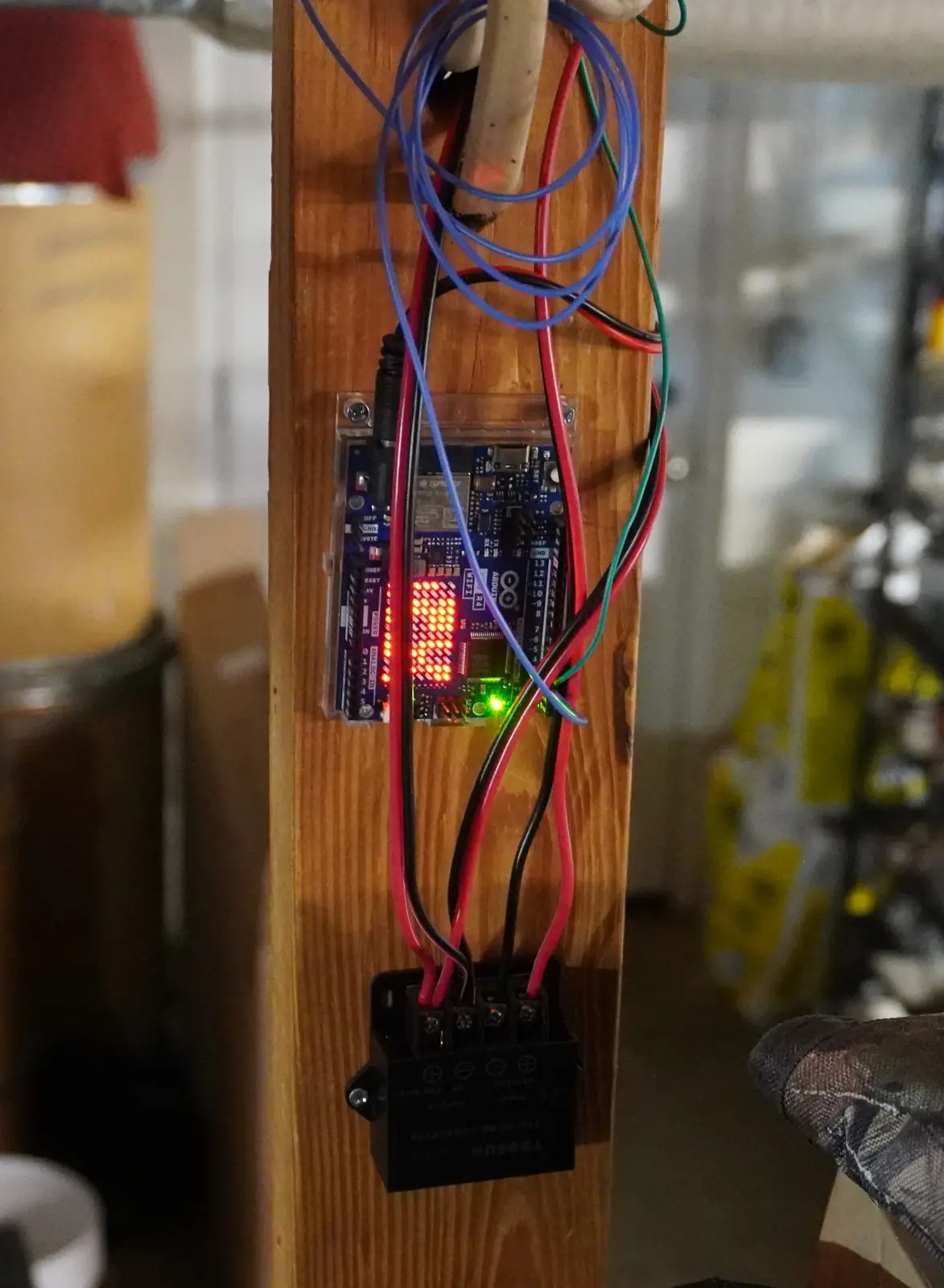

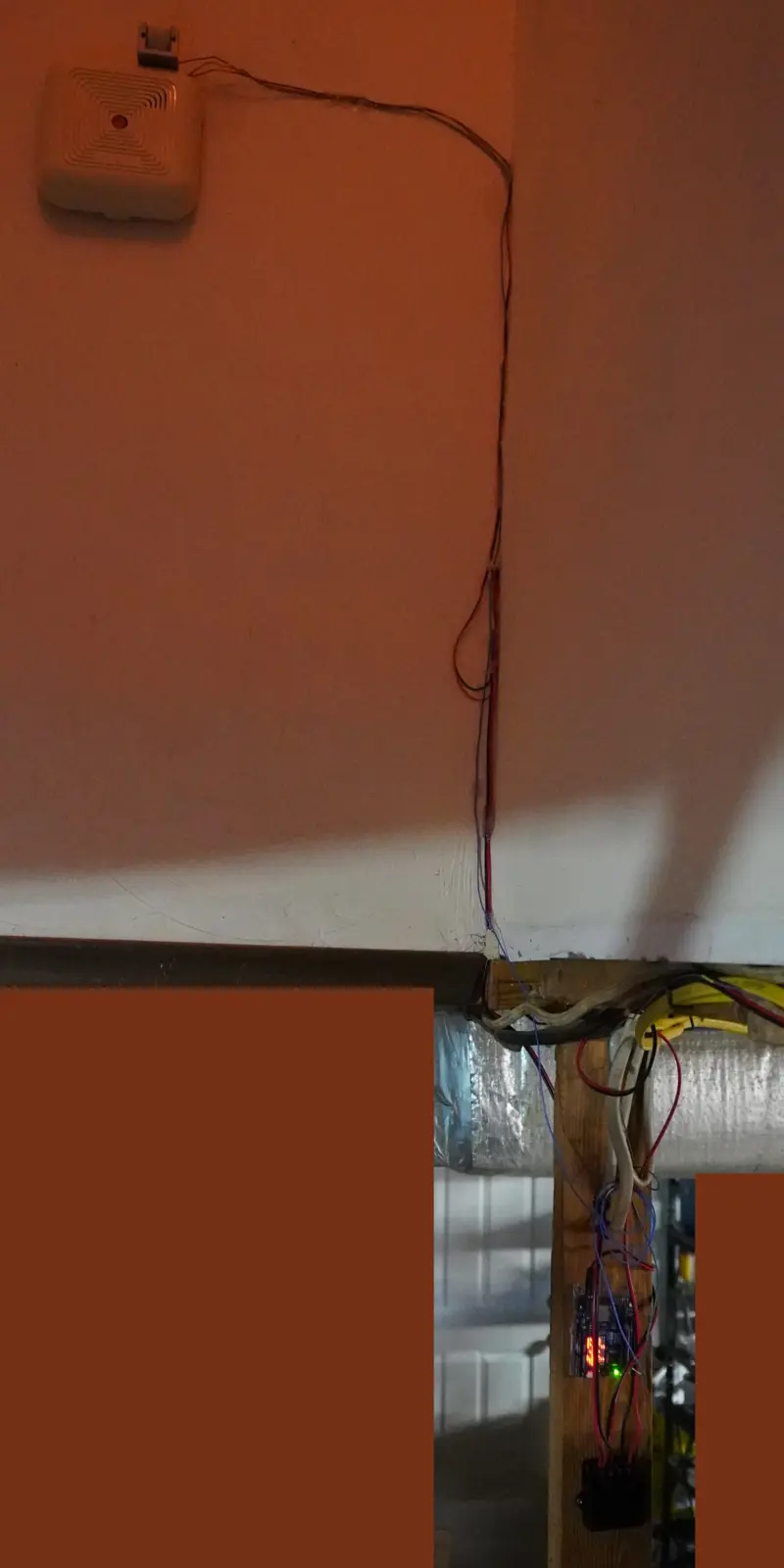

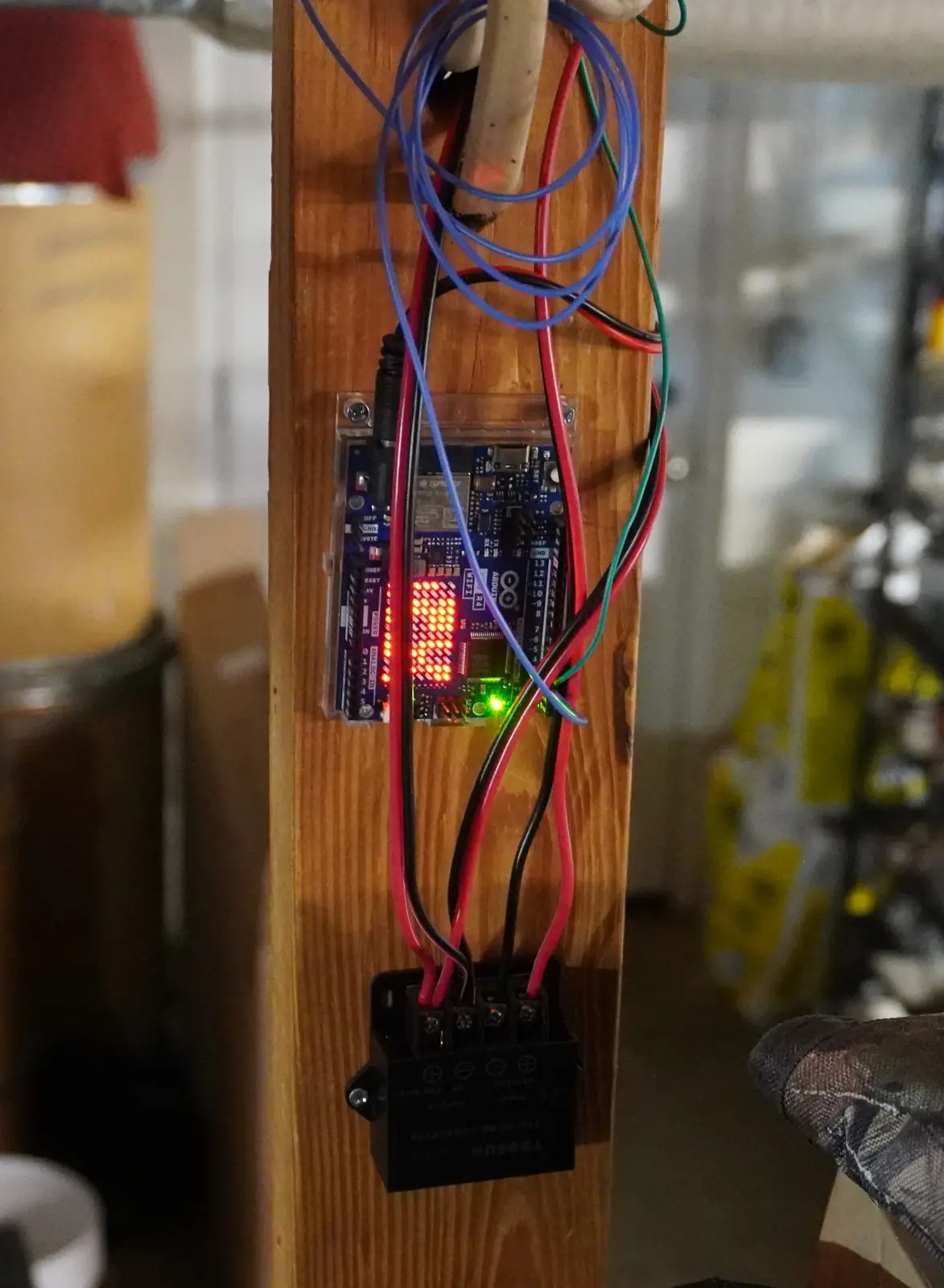

Stairwell Motion Light

Motion sensor on opposing wall and custom light bar

- • Designed to integrate with existing environment

- • PIR motion sensor on the "headout" triggers for up/downstairs correctly

- • Arduino interprets PIR and triggers relays

- • Custom resin lightbar with 12V LED vehicle-style lamps

Hallway Motion Nightlight (v1)

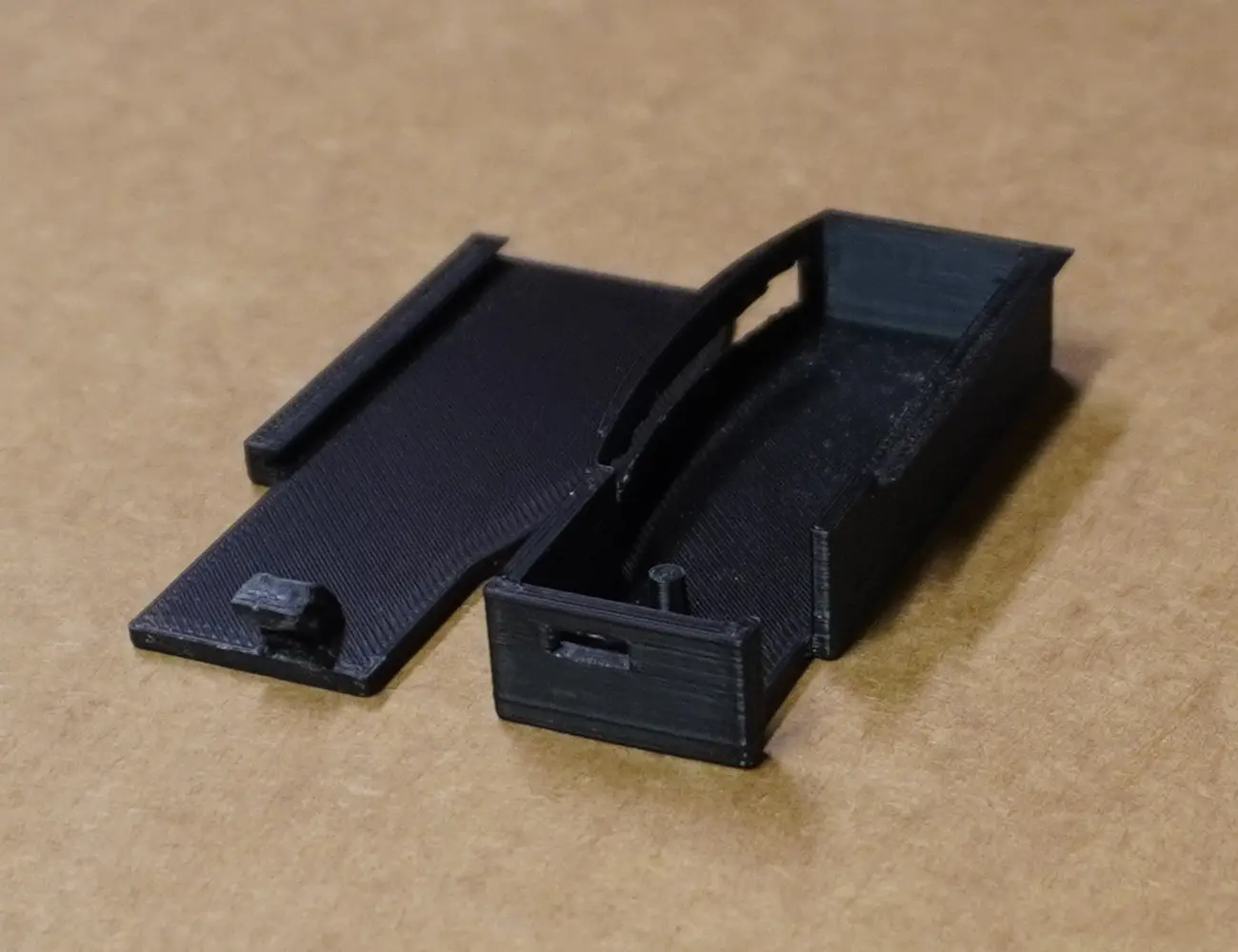

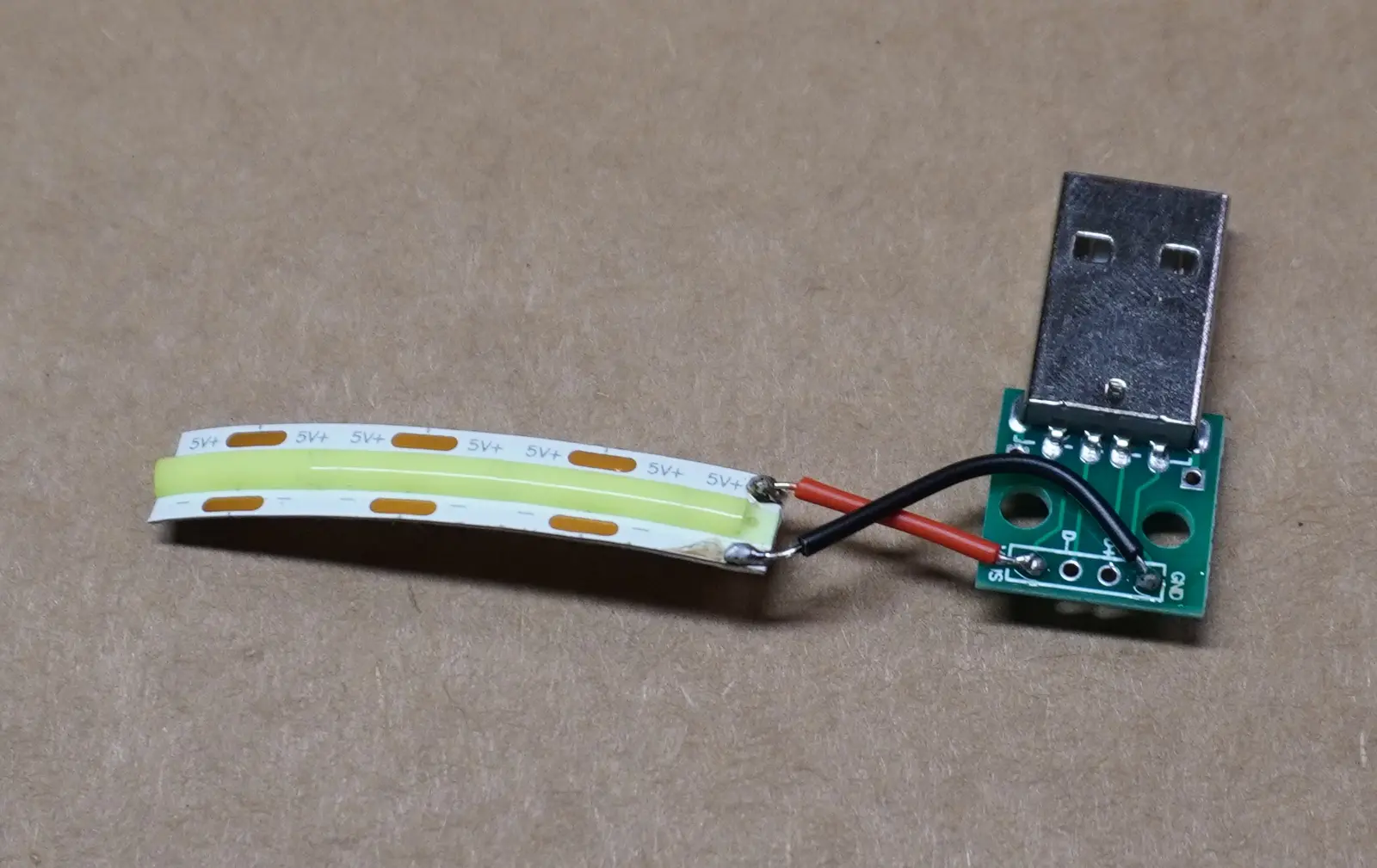

This project is a solution for safe nighttime navigation without harsh overhead lighting. The first successful integration is direct 5V from USB to the LED strip. The design is ready to integrate a PIR motion sensor and microcontroller. Those components can let the LED be PWM limited to low output until motion is detected. Using the USB interface avoids exposing 120VAC and allows economical wall adapters of many varieties.

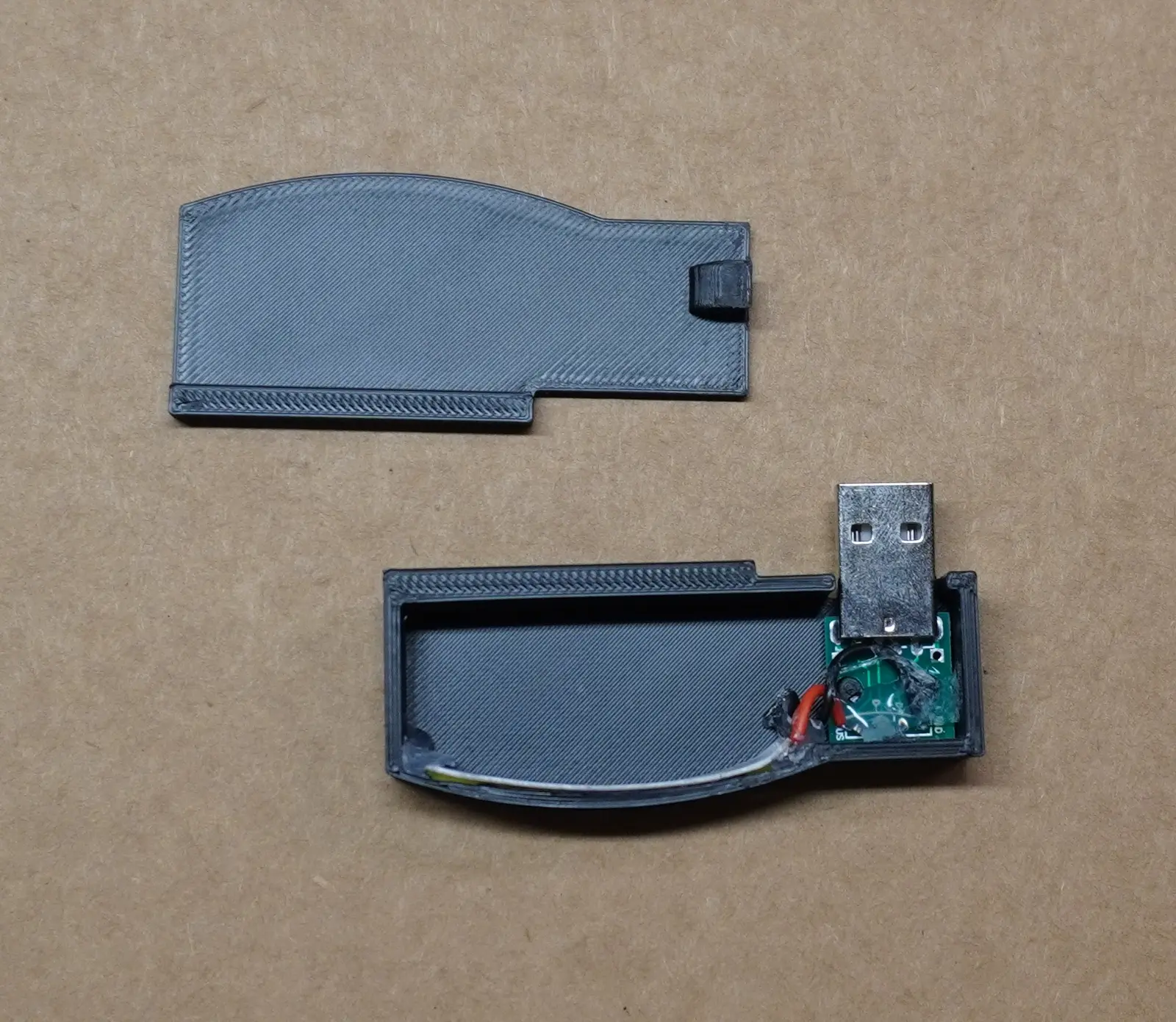

Key challenges included managing wire routing within a compact space, designing an effective light diffuser and LED length for soft ambient glow, and ensuring the enclosure could be assembled and serviced easily. Multiple iterations refined the retaining features and LED mount aperture. Wire management would be quite different with a microcontroller.

What I Learned / Iteration Notes

- • Curved face designs limit 3D FDM retaining features

- • Change the wiring cross pattern to black under red in this case

- • This silicon diffuser did not compress lock as well as expected

- • Hot glue can be handy but, like soldering, there is an art to it

Project Gallery

Finished assembly, front view

Internal components and wiring

Finished open

Lighting the hallway green

In use closeup

Distant low-light capture

Design Screenshots

Fusion 360 - Main enclosure design

Assembly view with all components

Watering Can Base (Branding / Labeling Variants)

An indoor watering solution vs metal outdoor cans or traditional plastic designs. The base is oval and wide for stability with a unique textured grip. Different caps / spouts can be interchanged based on the plant's watering needs.

This project explored how different embossing depths and geometries affect both aesthetics and print time. It also tests not just water tightness, but handling a PLA FDM printed object of weight while wet.

What I Learned / Iteration Notes

- • Weight distribution testing with filled can informed final base geometry

- • Embossing depth vs. print time (and failure) tradeoff — shallow reliefs print faster, but will less tactile effect when wet

- • Embossing or extruding letters on a curved face pushes software limits

- • Water division between spouts is good, but could be better with a higher and steeper dome apex

Project Gallery

Textured handhold and labeled

Branding ExE example

Lettering and texture zoom

Shower and pour spout in one

Assembled base and spout top

Fusion Design

Fish Food Shaker (Threaded + Dispensing)

A custom container for controlled fish food dispensing with a threaded, dump-resistant lid. The design includes precision holes for portion control and a thread profile optimized for 3D printing tolerances.

Thread design required multiple test prints to achieve smooth engagement without binding. Material selection considered food-safe filament options and moisture resistance for aquarium environments.

What I Learned / Iteration Notes

- • Thread pitch and clearance are critical — 0.2 - 0.4mm tolerance worked best for PLA

- • Embossing with curves vs sharp angles and printing text vertical

- • Dispensing hole size impacts portion consistency — multiple sizes tested

- • Ribs on the cap solved a visual consistency issue with the cap holes layer and provided support

Project Gallery

Assembled shaker, closed

Shaker holes and ribs

Threads are great, but there is a sane upper limit. ;)

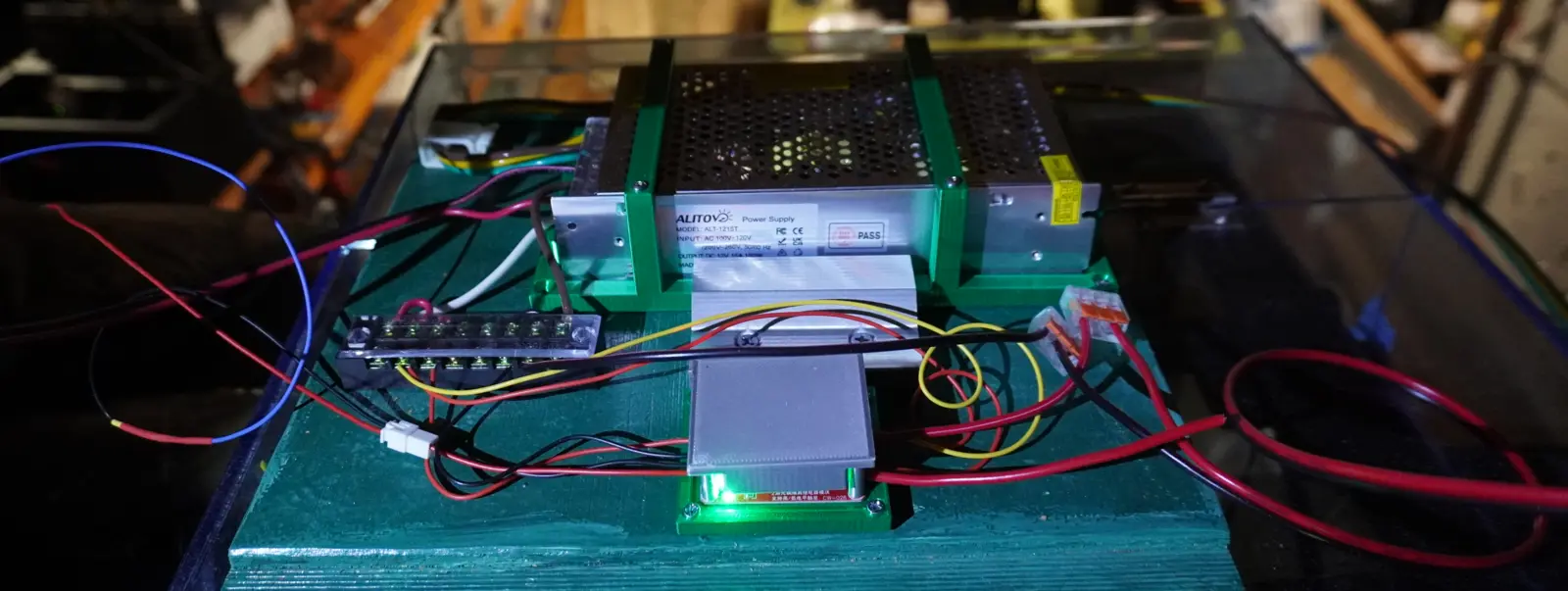

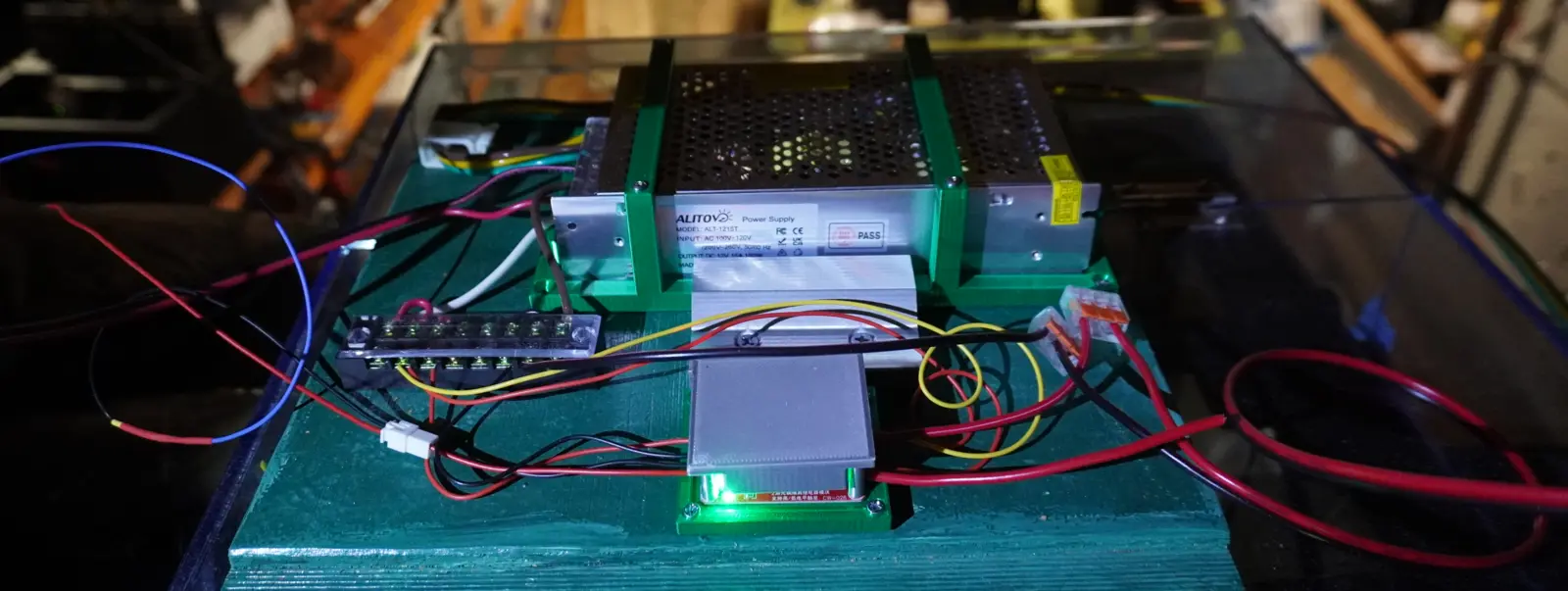

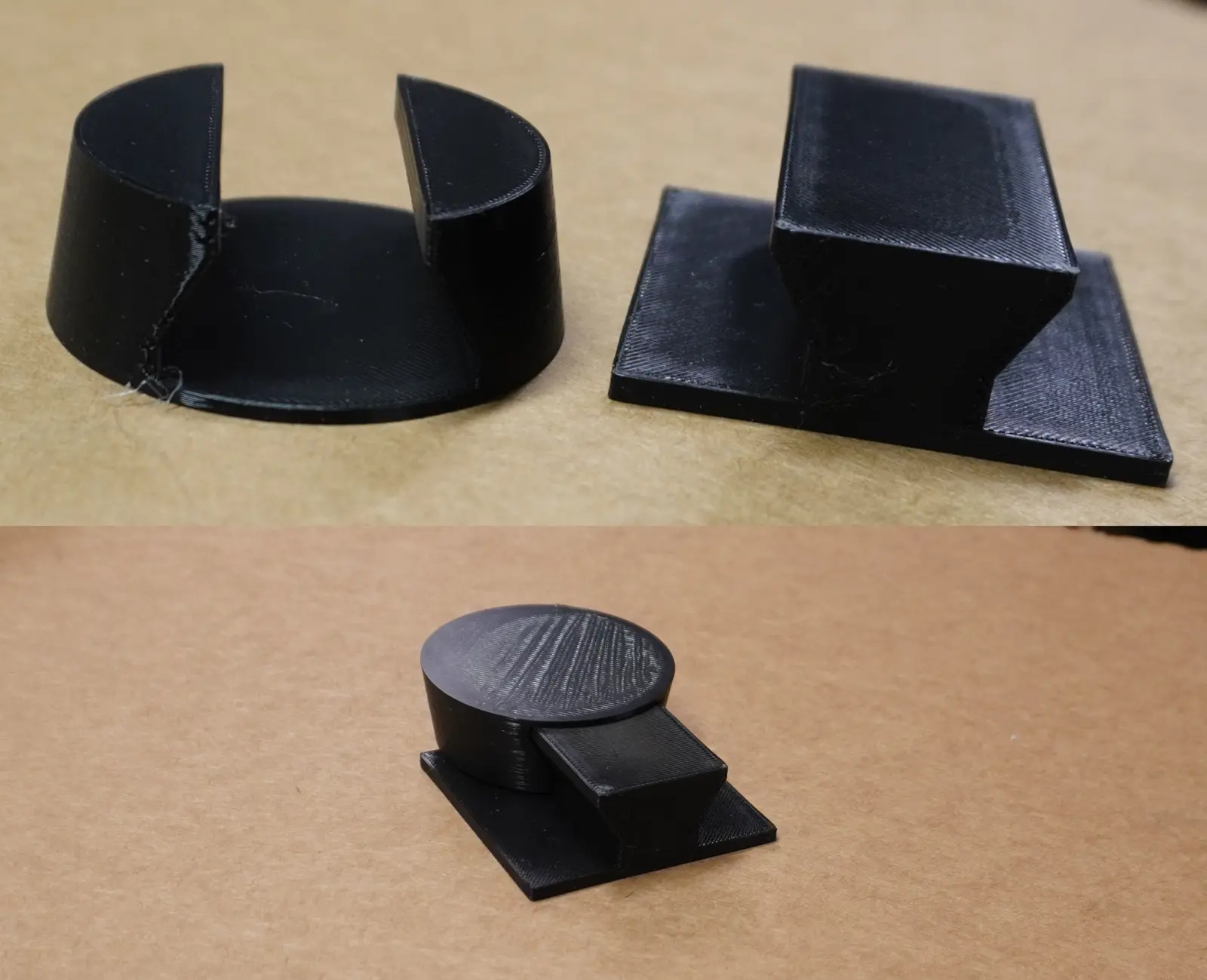

Stairwell Motion Light

A multi-part motion and lighting solution for a complex location. The lightbar is red tinted epoxy/resin, specially mounted above the door frame, and contains two vehicle running lamp equivalent LEDs. The system is powered by 120V AC input 12V DC output PSU. The PIR is mounted on the wall to catch the door opening and people ascending only trip the sensor when halfway up, thus preventing accidental tripping by people walking below

After creating the lightbar, this project had been on hold for months and was a major tipping point to start printing my own parts. Felt great to be able to put the electronics in place and see them work.

What I Learned / Iteration Notes

- • Resin has some mild weight so some snap testing was performed for the PLA. :)

- • Lots of tiny wire splicing and soldering before making any usable connections

- • Don't put bracket mount holes too close to edges and corners

- • Center of mass isn't always where expected, but lead weights work in a pinch

Project Gallery

Resin and 12V LED lightbar

12V power supply and relays

Sensor and controller layout

PIR as mounted on defunct fire detector

Arduino powered for automation expansion

Fusion Design

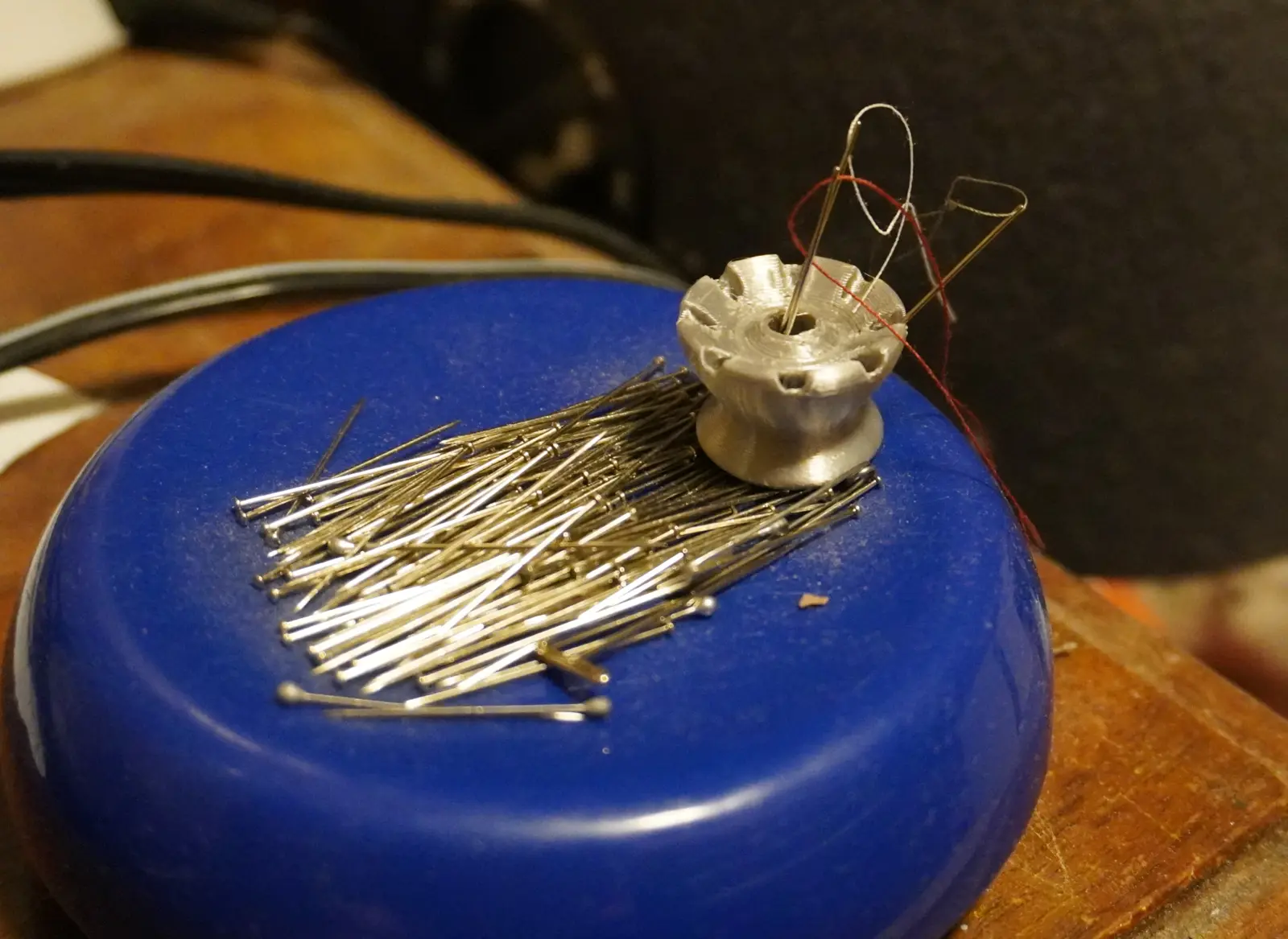

Exploratory & Early Prototypes

Explorations, test prints, and early prototypes — included to show process and iteration

Magnetic sewing needle and pin holder

Smaller version fits on standard mag holder

V-groove-like parametric organizer drawer

Creases, strings, errant forms while learning

PETG and O-Ring test ready

Customizable in Python using CADQuery

Bushing / screw clamp for threaded rods

Trapezoidal rail guide and round base plate

Have an idea? I can prototype it.

From concept sketches to functional prototypes, I bring experience in iterative design, material selection, and manufacturing constraints.

ContactWhat We Do

Comprehensive digital fabrication services for makers and businesses

Custom & Commission Prints

Unique prints made to order, either directly or through our designer network.

Design Brokerage

Connecting clients with skilled CAD designers for product development.

Printable Design Support

Helping refine or repair models to be manufacturing-ready.

Rapid Prototyping

Small-batch production for prototypes, marketing samples, or limited runs.

Replacement Parts on Demand

Functional reproductions, repair components, or discontinued parts.

Future Capabilities

Laser engraving, precision milling, and integrated smart device components.

Coming Soon

We're currently building out our fabrication network and workflow automation.

Interested in collaboration, early access, or prototype work?

Reach out — we're open to partnerships and pilot projects.

Get In Touch

Whether you're looking for custom fabrication services or exploring collaboration opportunities, I'd love to hear from you.